Stainless Steel

Precision cutting of stainless steel tubes stationary

Cutting tubes made from stainless steel, a corrosion-resistant alloy known for its durability, is challenging due to their high hardness and thermal resistance. The material also hardens during cutting, making it tougher as the blade progresses, while its low thermal conductivity leads to hot spots and potential blade damage. Additionally, stainless steel forms tough chips that require efficient removal to maintain cutting performance. To ensure clean and precise cuts, specialized saw blades, proper cooling, controlled speeds, and stable clamping are essential.

COMMON APPLICATIONS FOR STAINLESS STEEL TUBES

Stainless steel tubes are widely used in industries where corrosion resistance, hygiene, and long-term durability are essential for the end product's quality and functionality. These include the food and beverage industry, automotive, construction, chemical processing, medical sector, and marine environments. Typical applications include heat exchangers, sanitary piping, exhaust systems, handrails, medical instruments, structural tubing, and components exposed to moisture, chemicals, or high temperatures.

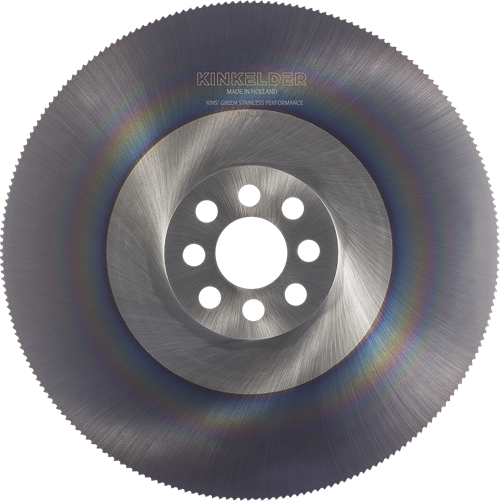

DISCOVER SAW BLADES FOR STAINLESS STEEL TUBE CUTTING

KINKELDER offers a wide range of products for stainless steel cutting. The TCT KINS' BLUE Stainless saw blade is made for high performance on high-end automatic sawing machines and HSS KINS' GREEN saw blades, like the KINS’ GREEN Stainless Performance, are specially designed for cutting stainless steel tubes, pipes, and profiles. The HSS KINS' GREEN Stainless Stabilizer is used to handle vibrations caused by material and/or sawing machine well. The KINS’ GREEN Universal is a versatile blade suitable when both stainless and ferro steels are cut without changing the blade.

For choosing the right saw blade for your application and sawing machine, you can contact our sales representatives or application engineers.