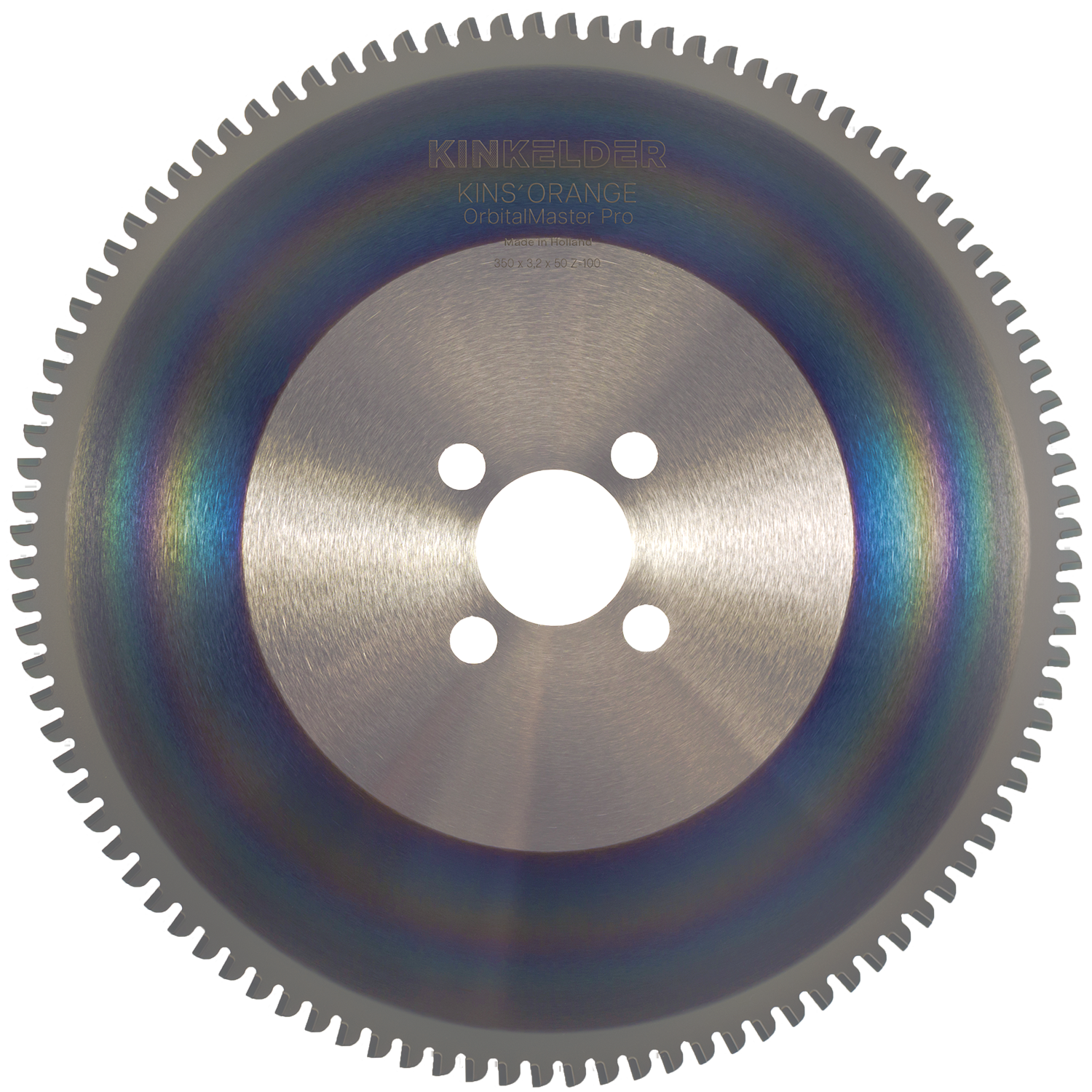

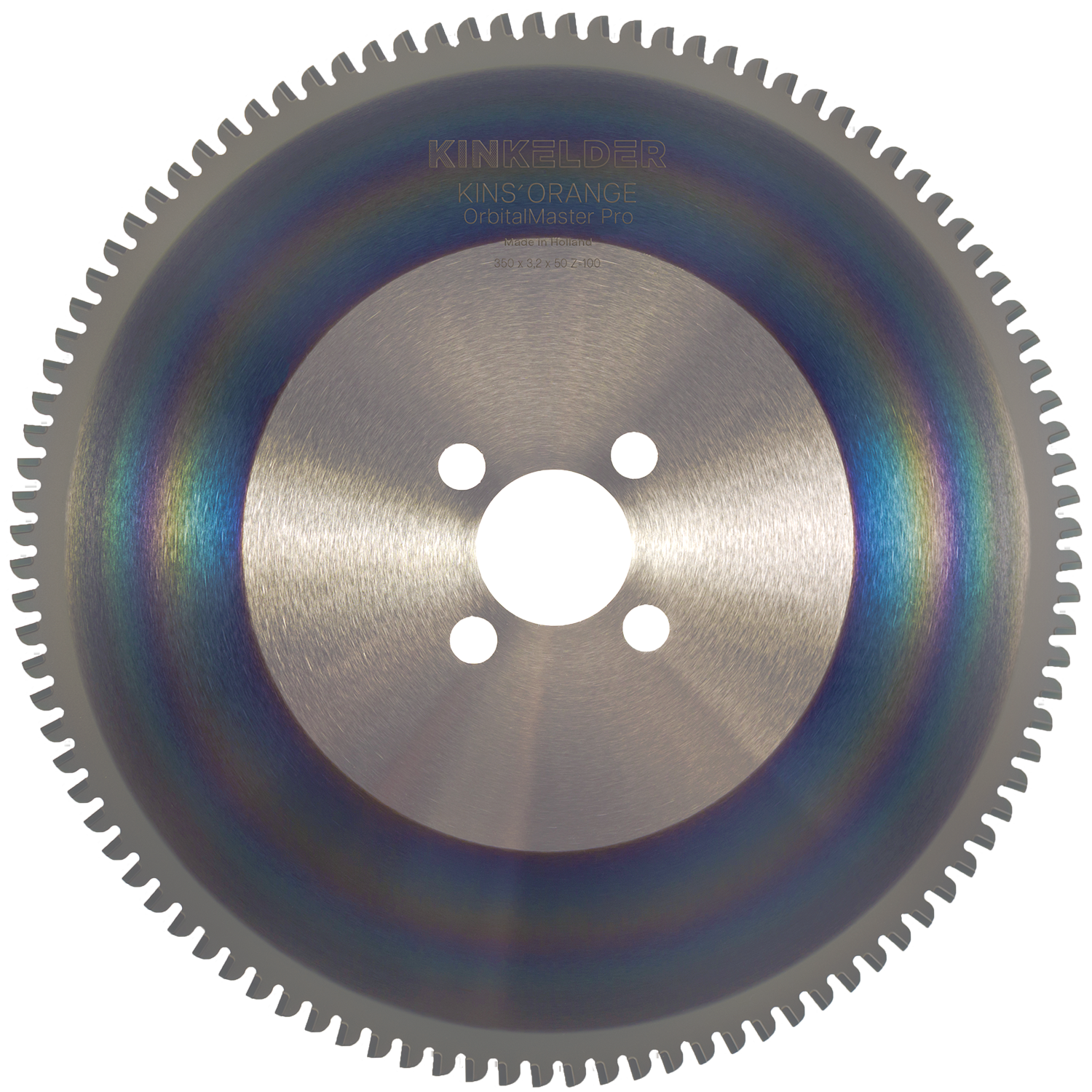

KINS' ORANGE OrbitalMaster Pro

Orbital flying cut-off on tube mills

KINS‘ ORANGE OrbitalMaster Pro TCT saw blades set the new standard for orbital flying cut-off applications on tube mills. This saw blade delivers even greater results due to an improved carbide grade for the tips, an optimized tooth geometry, and a new high-performance PVD coating.

-

Carbon Steel

-

Stainless Steel

-

Scarf

-

Blade Life

-

Profile

-

Tube