Scarf Tube

TUBE PRODUCTION WITH INSIDE SCARF REMOVAL

The term ‘inside scarf’ typically refers to the longitudinal weld bead from the inside surface of a steel tube. A removed scarf in the tube can disrupt cutting and reduces blade life. KINKELDER offers special blades that can handle tube cutting with a loose scarf inside, ensuring longer blade life than standard tube cutting blades.

COMMON APPLICATIONS OF TUBES WITH INSIDE SCARF

Cutting tubes with inside scarf is essential in industries that require smooth internal surfaces without weld bead interference. The automotive industry requires smooth internal surfaces for components like hydraulic and fuel lines, exhaust systems, and structural tubing. The oil and gas industry benefits from inside scarf removal when manufacturing pipeline tubing, drill pipes, and casing tubes that require seamless internal flow.

In the hydraulic and pneumatic sector, tubes with inside scarf removal are essential for cylinders and fluid transfer lines, preventing obstructions and ensuring efficient flow. The furniture and appliance industry also uses these tubes for aesthetic and functional applications, such as chair frames and structural supports.

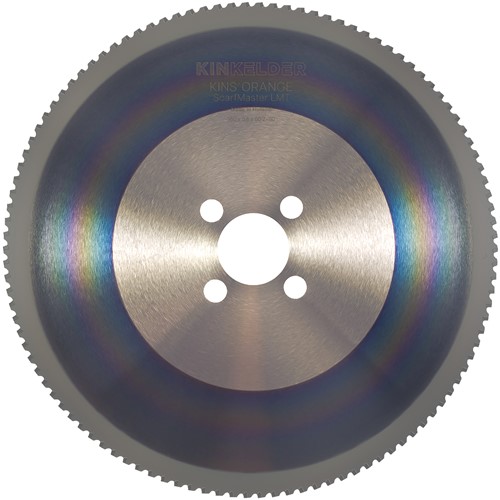

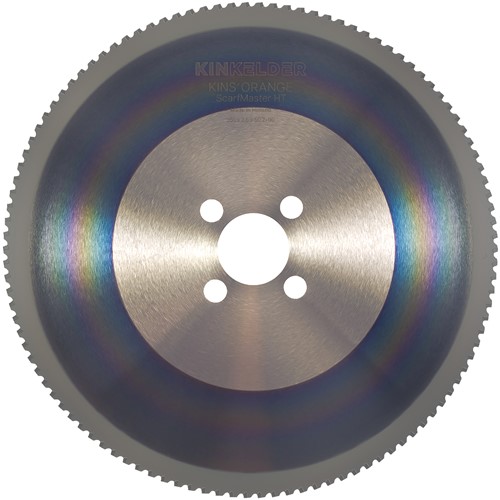

DISCOVER KINS’ ORANGE TCT SAW BLADES FOR CUTTING TUBES WITH ID SCARF

The KINS’ ORANGE range offers 2 specific KINS’ ORANGE saw blades, designed for cutting high-tensile or low-medium tensile steel tubes on flying cut-off application with internal weld bead removal.