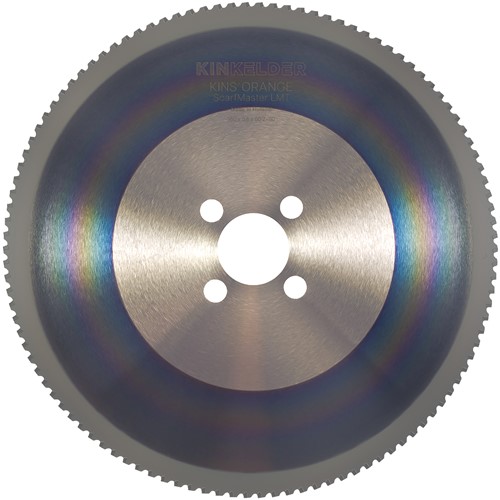

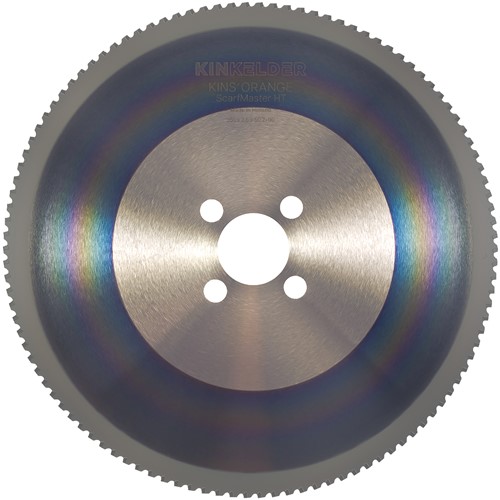

KINS' ORANGE OrbitalMaster

Orbital flying cut-off on tube mills

KINS' ORANGE OrbitalMaster TCT saw blades is the standard in orbital flying cut-off on tube mills. With its unique combination of fracture-resistant carbide tips, protected by a cutting-edge PVD coating, KINS’ ORANGE OrbitalMaster empowers a high blade life, and high line speeds.

-

Carbon Steel

-

Stainless Steel

-

Scarf

-

Blade Life

Explore the possibilities within our wide range to optimize your sawing process

By exploring our sawing blades you can discover new ways to enhance efficiency, precision, and TCO of your sawing processes.